Hitek Engineering Mechanical Shop maintenance is a fully equipped with sophisticated machineries for in-house repair, overhauling & testing including provision of round the clock services of skilled & trained field service technicians experienced in all types of static, rotating & reciprocating equipment, maintenance &repair services for Pumps, Turbines, Engines, Compressors and various other oilfield equipment such as Well Head & Christmas Tree equipment, Slush Pump Modules, Hoists, Hooks, Swivels etc. Instrumentation, Valve servicing, overhauling and testing of all types of Valves & Instruments including provision of onsite maintenance services during planned shutdowns with well-equipped portable workshops & trained and competent technicians.

Mechanical Services

Oil Field Services

Valve Services

Electrical Repair & Solution

Field Services

Machine Shop

Welding & Fabrication Shop

Special Process

TROUBLE SHOOTING AT SITE

Dynamic Balancing Machine

Testing Capabilities

Mechanical Services

Rotating

- Centrifugal/ Reciprocating Pumps Overhaul, Repair & Maintenance

- Centrifugal/ Reciprocating Compressors Overhaul, Repair & Maintenance

- Impulse/ Reaction Steam Turbine Overhaul, Repair & Maintenance

- Gear box Overhaul, Repair & Maintenance

- Gas Turbine Rotors Overhaul and Repair

- Performance and Material Upgrades and enhancement

- In-Situ Pre-Overhauling diagnostics and Investigation

- Condition monitoring & Vibration analysis

- Alignment services

- Static/ Dynamic Balancing of Rotors

- Cryogenic pumps repair & Overhaul

- Over haul and repair of heat exchangers (Tube and Plate type)

- Re-tubing of heat exchangers

- Repair and overhaul of columns

- Repair of Gas Turbine Stator Vanes and diaphragm

- Repair and overhaul of oil field ancillary equipment

- Overhauling and repair of Pneumatic Cylinders

- Overhauling and repair of Hydraulic cylinders

- Overhauling and repair of Drilling Rig equipment

- Valves Repair and Calibration

Static

Oil Field Services

Oilfield services include manufacture, repair and remanufacture of oilfield products & accessories such as:

Oilfield services include manufacture, repair and remanufacture of oilfield products & accessories such as:- API 5CT Tubing & Casing Pup Joints, Tubing & Casing Couplings, Threading of Casing & Tubing joints, Casing & Tubing Drifts and manufacture of accessories..

- API 7-1 Drill Stem Subs & Threading for Rotary Shouldered Connections.

- API 6A Crossover Connectors, Top Connectors, Adapter & Spacer Spools, Flanged Connectors, Threaded Connectors & Other End Connectors..

- API 16A Drilling Spools, Adapters & Loose Connections.

- API 16C Drilling Choke, Standpipe Manifolds and Kill Manifolds.

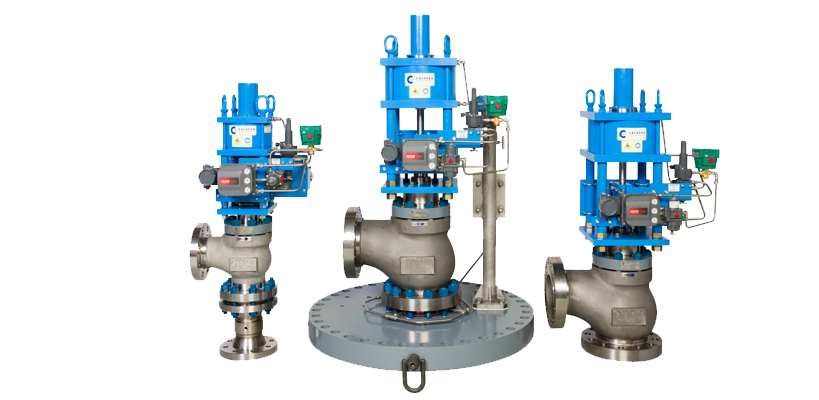

Valve Services

Provision of specialist Technicians and facilities to complete the following:

Provision of specialist Technicians and facilities to complete the following:

- Overhaul and repair of all types and makes of Isolation Valves, Manually Operated Valves, Motor Operated Valves, Non-return and Check valves, Control Valves and Pressure Safety Valves (PSVs).

- Overhaul and repair of Valve accessories and associated equipment such as Actuators, gearboxes, positioners etc.

- Testing and certification to international standards.

- General engineering support to maintenance teams and operators.

- Any other services which are within the specialist capabilities of the contractor.

- In-situ overhauls and repairs of all types and makes of Valve accessories and associated equipment such as actuators, gearboxes, positioners etc.

- On-line valve flushing, lubrication maintenance and emergency sealing.

- Provision of Equipment and Operators to allow access to valves and equipment which are subterranean, at a height or otherwise inaccessible.

- Provision of specialist technicians and facilities to complete the following:

- Valve improvement – specification developments, retrofits and upgrades.

- Emergency repair.

- Shutdown activity planning – including work list development and work order creation.

- Replacement valve and spares specification development and procurement.

- Inventory management.

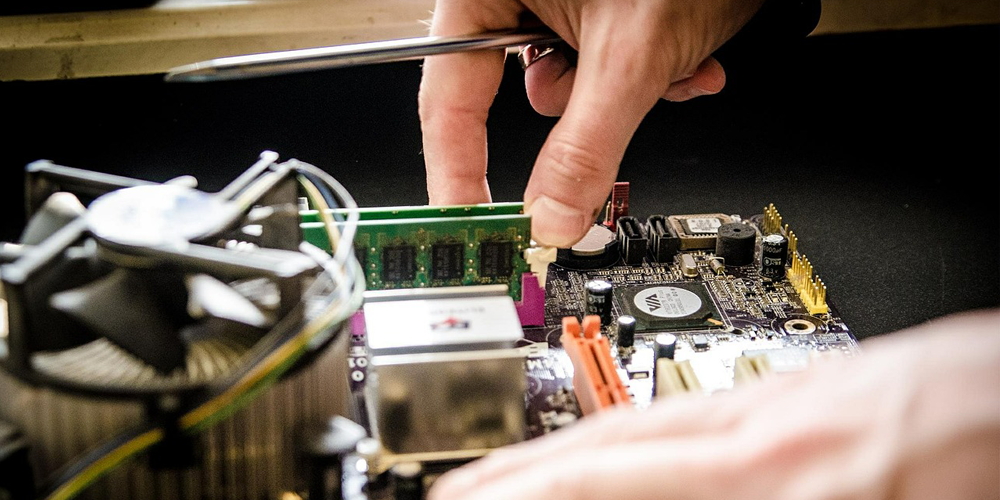

Electrical Repair Solution

Hitek Engineering offers a wide range of electrical repair solutions such as:

Hitek Engineering offers a wide range of electrical repair solutions such as:Rewinding, Repairing, Overhauling of all types of Motors (AC/DC), Generators, Alternators, Submersible pumps including IEC Ex / ATEX Explosion Proof/Flame Proof designated motors/generators/submersible pumps.

Furthermore, we provide a 24/7 assistance & service for emergency repair to any type of AC/DC rotating machines on-site and Offshore.

Service Capacity/Ranges

- Rewinding & overhauling capabilities of the facility are as under:

- MV and HV Induction Motors (AC): 150 KW to 10,000 KW – (1.1 KV to 13.8 KV)

- Slip Ring Motors: 150 KW to 6000 KW – (380 Volts to 6,600 Volts )

- Low Voltage Squirrel Cage Induction Motors: 0.5 KW -1000 KW (230 to 690 Volts)

- Submersible Pump Motors: 0.37 KW – 1000 KW (230 to 3,300 Volts)

- DC Motors Including Traction Motors: 1KW – 4000 KW ( 110 to 800 Volts)

- Generators AC / DC: 1 KVA – 5000 KVA (110 to 11,000 Volts)

Field Service

Skilled Field Service Technicians are available on short & long term call basis including planned shutdowns for both offshore and onshore locations to carry out installations, in-situ servicing, repairs, overhauls, and refurbishment of all types of static, rotating and reciprocating equipment, including wellhead maintenance, valve overhauling etc. Also available are the services of qualified coded Welders, Fabricators, qualified Welding Inspectors, skilled Machinists, Fitters, General Technicians, QC Inspectors, Valve Technicians, Instrument technicians, NDT technicians, Heat Treatment Technicians, Engine Mechanics, Electricians, Planning Technicians, Fork-lift Operators Spray Painters and general assistants..

Skilled Field Service Technicians are available on short & long term call basis including planned shutdowns for both offshore and onshore locations to carry out installations, in-situ servicing, repairs, overhauls, and refurbishment of all types of static, rotating and reciprocating equipment, including wellhead maintenance, valve overhauling etc. Also available are the services of qualified coded Welders, Fabricators, qualified Welding Inspectors, skilled Machinists, Fitters, General Technicians, QC Inspectors, Valve Technicians, Instrument technicians, NDT technicians, Heat Treatment Technicians, Engine Mechanics, Electricians, Planning Technicians, Fork-lift Operators Spray Painters and general assistants..

Machine Shop

The shop floor is well equipped with all types of modern heavy duty, precision machine tools including sophisticated CNC machine tools such as Heavy duty Vertical & Horizontal Boring machines, Large bore Hollow Spindle Lathes specializing in the machining & threading of OCTG & Drill Stem elements including manufacture, repair & remanufacture of Wellhead & Christmas tree equipment, Drill-through equipment & Slush Pump Modules, Manufacture of Orifice Plates, Orifice Flanges, Drip rings, Thermo-wells, Spades, Spectacle blinds, Tubing & Casing Drifts, Quick Hammer Union sets etc

a) CNC Hollow Spindle Lathe

b) Horizontal Boring Machine

Spindle Diameter: 130 MM

X- Travel: 2240 MM

Y- Travel: 1600 MM

Z- Travel: 2000 MM

c) Vertical Lathe Machine

d) Hollow Spindle Lathe

Bed type -VEE

e) MAS VR8 Radial Drilling Machine

Max Drilling Capacity (MM)- 90

Distance arm end to column center line (MM)- 3300

Vertical Elevation of Arm (MM)- 1000

Max distance Spindle Nose to machine base (MM)- 2100

f) Lathe Machine

g) Universal Milling Machine

h) Surface Grinder

Table size Y: 350 MM

Table Magnet size: 1500 MM x 260 MM

i) Shaper Machine

k) Water Jet Cutting

2 x 6mtr bed size

Thickness up to 85mm

l) Laser Cutting

2 x 3mtr bed size

Thickness:

MS steel up to 20mm

SS steel up to 15 mm

m) Profile Cutting

Thickness up to 200mm

n) Hydraulic Press

Welding & Fabrication Shop

We do all types of Fabrication & Welding works by qualified welders for various grades of metals.

Services also include Cladding, Hard Facing, Brazing and Cemented Carbide Dressing. Highly skilled

Fabricators and qualified Welders undertake all kinds of fabrication and welding works involving various

procedures for Carbon Steel, Low Alloy Steels including Stainless Steel overlays to facilitate the repair

and remanufacture of valves and wellhead equipment, refurbishment of Stabilizers with cemented carbide

dressing ground to gauge size on cylindrical grinder. Moreover, onsite fabrications and other general welding servicesare also undertaken. Also available in-house are the Stress Relieving / Heat Treatment facilities.

We do all types of Fabrication & Welding works by qualified welders for various grades of metals.

Services also include Cladding, Hard Facing, Brazing and Cemented Carbide Dressing. Highly skilled

Fabricators and qualified Welders undertake all kinds of fabrication and welding works involving various

procedures for Carbon Steel, Low Alloy Steels including Stainless Steel overlays to facilitate the repair

and remanufacture of valves and wellhead equipment, refurbishment of Stabilizers with cemented carbide

dressing ground to gauge size on cylindrical grinder. Moreover, onsite fabrications and other general welding servicesare also undertaken. Also available in-house are the Stress Relieving / Heat Treatment facilities.

Our welding methods include

- TIG/MIG

- SMAW

- GTAW

- GMAW

- FCAW

Special Process

Special Process includes: specialised Welding & Thermal Spray Application (TSA) including High Velocity Oxy Fuel (HVOF), anti-galling treatments like Manganese & Zinc Phosphate Surface Treatments, Stress Relieving/Heat Treatment.

Special Process includes: specialised Welding & Thermal Spray Application (TSA) including High Velocity Oxy Fuel (HVOF), anti-galling treatments like Manganese & Zinc Phosphate Surface Treatments, Stress Relieving/Heat Treatment. NDT methods

We have in house Magnetic Particle Testing & Liquid Penetrant Testing. Also available in-house are portable Hardness Testers for identifying hardness values of various metals & Positive Material Identification (PMI) equipment for identifying the composition of various metals.

TROUBLE SHOOTING AT SITE

We provide aftermarket services for stationary

and rotating equipment in Water treatment

plants, Power stations, Cement plants and Oil &

Gas industries throughout MENA region.

The repair and overhauling activities performed

will meet all statutory requirements .We have

developed methods and procedures to conduct

overhauling and ensure that all work is

performed with proper documentation.

We have highly experienced supervisors and

technicians who can visit site on request and

inspect and discuss with client engineers and

supervisors about problems faced in site and

recommend remedial measures.

Field repair or repair in workshop will be decided

in consultation with client and Hitek will attempt

to refurbish the equipment as early as possible.

Overhauling of equipment will be performed

strictly as per work scope agreed with client.

We provide aftermarket services for stationary

and rotating equipment in Water treatment

plants, Power stations, Cement plants and Oil &

Gas industries throughout MENA region.

The repair and overhauling activities performed

will meet all statutory requirements .We have

developed methods and procedures to conduct

overhauling and ensure that all work is

performed with proper documentation.

We have highly experienced supervisors and

technicians who can visit site on request and

inspect and discuss with client engineers and

supervisors about problems faced in site and

recommend remedial measures.

Field repair or repair in workshop will be decided

in consultation with client and Hitek will attempt

to refurbish the equipment as early as possible.

Overhauling of equipment will be performed

strictly as per work scope agreed with client.

Dynamic Balancing Machine

Model: CAB 920

Make: Schenck

Capacity: 10 kgs. Up to 10 Tons

Excerpt from ISO 1940 – Quality Grades

- G 2.5

- G 1.0

- G 0.4

- G 6.3

- G 16

Testing Capabilities

Testing Capabilities

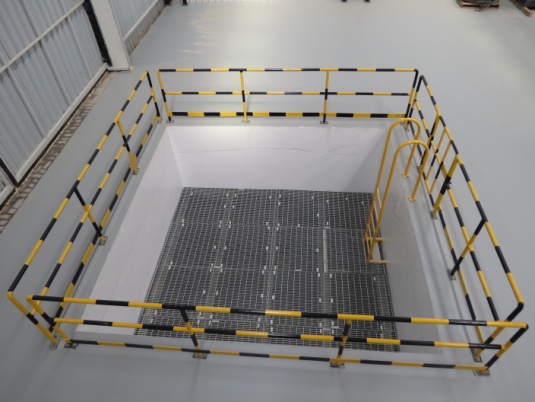

- Dimensions: Length = 5 mtrs X Width = 4 mtrs X Depth = 4 mtrs

- Hydrostatic test of any types of valves, Pumps & Pipe manifolds.

Pump Testing Capabilities:

- Test flow up to 4000 gpm

- Discharge pressure up to 2000 PSI

- Our pit is 15,850 Gallons equivalent to 60,000 liters supply tank.

- Calibrated magnetic flow meters monitor flow through 4000 gpm.

- Pump Works 610 test procedure based on API 610 criteria.

- Standards can be modified to meet specific customer requirements.